Hallo

Mijn voorbumper zakt weg en wil deze weer omhoog brengen

Wie weet daar een goeie manier voor en hoeveel tijd zit daar ongeveer in

Wat moet allemaal verwijderd worden

MG ZT 135 2007 cdti

Groet Gerard

voorbumper zakt

- gerardfennema

- MG-R Regular

- Berichten: 33

- Lid geworden op: zo okt 05, 2014 11:26 am

- Woonplaats: Muntendam

- Locatie: muntendam

Re: voorbumper zakt

Ik weet niet of je lid bent van het forum in de UK maar daar vind je het volgende;

http://www.the75andztclub.co.uk/forum/s ... hp?t=41195" onclick="window.open(this.href);return false;

http://www.the75andztclub.co.uk/forum/s ... hp?t=41195" onclick="window.open(this.href);return false;

Jaguar XE

MG ZS 120 MKII

- gerardfennema

- MG-R Regular

- Berichten: 33

- Lid geworden op: zo okt 05, 2014 11:26 am

- Woonplaats: Muntendam

- Locatie: muntendam

Re: voorbumper zakt

Nee ben er niet lid van kan er niet op komen

-

Mista T

- MG-R Core

- Berichten: 2526

- Lid geworden op: do dec 19, 2002 12:36 pm

- Woonplaats: Nieuwegein

- Locatie: NIEUWEGEIN

Re: voorbumper zakt

Time to give my facelift a facelift.

Notes: You will need to read through and understand this thread first before proceeding with this task.

The car looked like this since I bought it, it was exagerated after it was resprayed. Notice how the bonnet line is low, and the bumper looks like it is hanging off, I tried to raise it the best I could but it looked the same. I thought it could not be done until Jules pointed in the right direction of raising the crash beam and slam panel. I went to work on it this morning.

Whipped off the bumper, (see thread mentioned above here: http://www.the75andztclub.co.uk/foru...ad.php?t=38392" onclick="window.open(this.href);return false;)

Note: The holes in the slam panel and the crash beam are much larger than the bolts to begin with, and they are square. Also the slam panel is only sandwiched between the crash beam and the framework and may slide down when bolts are undone, and you may end up just raising it back to where it was before you started wasting all your efforts.

I then marked the height of the slam panel from the ground from behind the crash beam at each side (I used a stick and put corresponding marks on the stick and panel, then made another mark 6-8mm higher to use as my guide for fitting), as seen in the pic below.

Before I removed 4 bolts and 1 nut from each end of the crash beam I marked the horizontal and vertical position of the crash beam in relation to the slam panel. Then when I raise the slam panel 6mm, then place the crash beam back in the same place against the slam panel. Then I know both the slam panel and crash beam have been raised 6mm from their original positions. I then withdrew the beam and elongated all 10 mounting holes by approx' 8mm (it it easier to have 2mm to much and be able to lower it a little than be 1mm short). I put a mark about 8mm below each hole to ease accurate filing deapth, and filed down to the marks (it also gives a better visual aid than having holes all deapths).

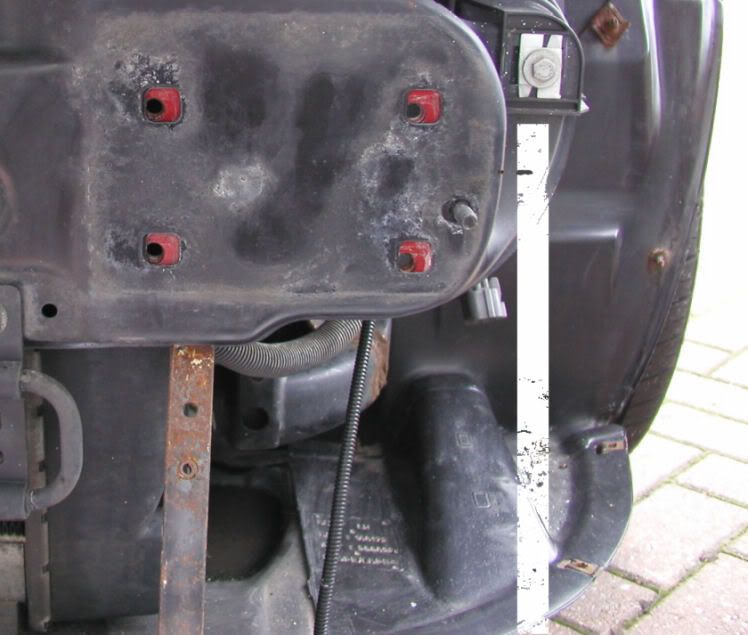

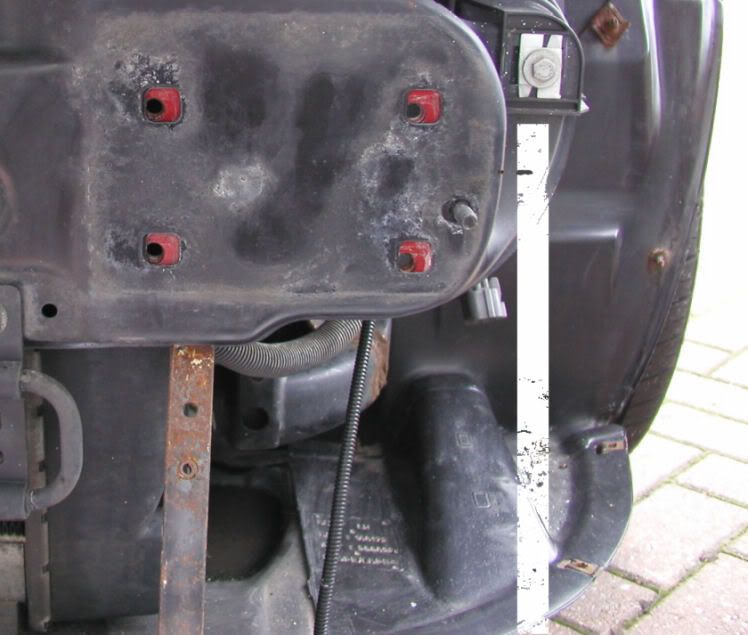

The vertical and horizontal slam panel position marks can be seen on the crash beam pic below.

Raising the slam panel is important because it in turn raises the headlights, allowing vertical movement of the bumper. Especially if the bumper is already tight under the headlights. I also removed the fir tree clips that prevented the bumper from being raised as much as was needed. It could not simply swivel on the fir tree clips, because raising the front would mean lowering the rear. so the whole bumper forward of the end blade and slot fittings had to be raised.

Pic below shows the top slam panel bolts removed with 3mm shims at the ready, once slam panel is raised the shims can go in to support the top of the slam panel.

Without needing to elongate the holes because the slam panel was at its lowest point on the bolts, I managed to raise the panel as high as it would go, and still get the bolts in, this was just enough. I fitted the crash beam, inserted bolts finger tight then pushed each side of the slam panel up as far as it would go without excess force, and supported it at each end. I then aligned the crash beam with the slam panel by using my marks, tightened up and removed slam panel supports. RESULT = crash beam and slam panel raised 6mm from original position.

Pic below shows 2 X 3mm shims to support the top of each end of the slam panel. It looks bigger than 6mm but it is not. Already you can see the bumper has been pulled up nicely to the wing.

I had raised the slam panel 6mm, luckily the bonnet line was low, so raising it was no problem if I wanted, I levelled with the wings by adjusting the sprung latch pins each side in the pic below, by pulling down on the spring exposing the 17mm locknut, and adjusting the pin until I was happy with the height. There is usually 4-6 full turns antclockwise before the pins are ejected by the springs, I adjusted 1/8 to 1/4 of a turn then checked the hright.. (It was fun trying to hold the bonnet up with my head, pull down on the spring, and undo the locknut).

TADA. How'd ya like them apples.

Well pleased. Many thanks to Jules for putting me on the track of crash beam and slam panel adjustment to alter the height of the bumper. Now to wash off the grubby marks.

I have tried to make the picture below exagerate the bonnet shutline gap above the grille.

I have the option of pushing the top of the bumper in and I could get away with lowering the bonnet a litle now, but as the pic below shows taken beforehand, I like this bonnet/grille line gap. The pic shows the bonnet was lower than the wings, and the bumper line was quite bad. It was a bright day and it was hard to take a pic without sun glare.

Another pic taken after the facelift's facelift. The lines are vastly improved

I cannot stress the importance of getting the slam panel and crash beam adjusted correctly from its original position, otherwise, right now I could be taking the bumper off to start all over again.

Notes and addendums

On rare occasions the yellow fir tree clip with the little ball on the end (seen on the concave part of the wing in pic 3 by Jules) comes out of the wing attached to the bumper. You just pull it out of its socket on the bumper and push it back into the wing. You then just line up the socket on the bumper( you will notice that this white socket is floating and is able to move up and down allowing vertical bumper movement) and push it onto the little yellow ball on the wing.

I believe it says in a manual somewhere to remove the fir tree clips from the wings, and push them into the bumper, this should only be done if the fir tree clips cannot be located into the socket on the wing, because they may break by needless removal or when refitting the bumper.

If you look close at the crash beam, you remove 4 bolts from each end and remove the crash beam. The single nut at each end holds the slam panel in place while you check its position for possible adjustment. If you look close at the 2nd pic in the how to you will see the slam panel is as high as it will go without stopping the bolts from going back in, luckily this was enough for me as the slam panel must have been resting on the bolts before they were tightened. I first removed a single bolt from each side of the crash beam, and noticed that the crash beam could not be pushed up without making the square holes a little bigger. You have to raise the slam panel because the infil strips tend to rest upon the crash beam so it is best to raise both equally.

Look at pic 5 in the how to, notice the horizontal position of the slam panel has not been altered, the holes each side of the slam panel are far bigger than the bolt, this allows minor adjustment. You will see by the ring made by the top bolt, that when the bolts are inserted and tightened, the slam panel will be in exactly the same place but a few mm higher.

If the forum is browsed you will find a number of threads relating to bonnet jamming and bonnet cable modification. Part is due to the design, part is due to poor bonnet locking pin alignment/lubrication, and the bonnet being on the verge of jamming each time it is released. The modification allows greater force to be applied to the release lever without the cable 2 into 1 assembly coming apart. You can pull your bonnet release and it may be happy to release, it may however be on the verge of poor alignment and may only need a mm or two out of alignment to cause it to jam

Disclaimer:

You are responsible for any work or modifications carried out on your car and you undertake any such work at your own risk. Neither the 75 and ZT Owners Club nor the original authors in this thread can be held liable for anything that may happen as a result of you following this thread's posts.

Any modifications should be reported to your insurance company.

Notes: You will need to read through and understand this thread first before proceeding with this task.

The car looked like this since I bought it, it was exagerated after it was resprayed. Notice how the bonnet line is low, and the bumper looks like it is hanging off, I tried to raise it the best I could but it looked the same. I thought it could not be done until Jules pointed in the right direction of raising the crash beam and slam panel. I went to work on it this morning.

Whipped off the bumper, (see thread mentioned above here: http://www.the75andztclub.co.uk/foru...ad.php?t=38392" onclick="window.open(this.href);return false;)

Note: The holes in the slam panel and the crash beam are much larger than the bolts to begin with, and they are square. Also the slam panel is only sandwiched between the crash beam and the framework and may slide down when bolts are undone, and you may end up just raising it back to where it was before you started wasting all your efforts.

I then marked the height of the slam panel from the ground from behind the crash beam at each side (I used a stick and put corresponding marks on the stick and panel, then made another mark 6-8mm higher to use as my guide for fitting), as seen in the pic below.

Before I removed 4 bolts and 1 nut from each end of the crash beam I marked the horizontal and vertical position of the crash beam in relation to the slam panel. Then when I raise the slam panel 6mm, then place the crash beam back in the same place against the slam panel. Then I know both the slam panel and crash beam have been raised 6mm from their original positions. I then withdrew the beam and elongated all 10 mounting holes by approx' 8mm (it it easier to have 2mm to much and be able to lower it a little than be 1mm short). I put a mark about 8mm below each hole to ease accurate filing deapth, and filed down to the marks (it also gives a better visual aid than having holes all deapths).

The vertical and horizontal slam panel position marks can be seen on the crash beam pic below.

Raising the slam panel is important because it in turn raises the headlights, allowing vertical movement of the bumper. Especially if the bumper is already tight under the headlights. I also removed the fir tree clips that prevented the bumper from being raised as much as was needed. It could not simply swivel on the fir tree clips, because raising the front would mean lowering the rear. so the whole bumper forward of the end blade and slot fittings had to be raised.

Pic below shows the top slam panel bolts removed with 3mm shims at the ready, once slam panel is raised the shims can go in to support the top of the slam panel.

Without needing to elongate the holes because the slam panel was at its lowest point on the bolts, I managed to raise the panel as high as it would go, and still get the bolts in, this was just enough. I fitted the crash beam, inserted bolts finger tight then pushed each side of the slam panel up as far as it would go without excess force, and supported it at each end. I then aligned the crash beam with the slam panel by using my marks, tightened up and removed slam panel supports. RESULT = crash beam and slam panel raised 6mm from original position.

Pic below shows 2 X 3mm shims to support the top of each end of the slam panel. It looks bigger than 6mm but it is not. Already you can see the bumper has been pulled up nicely to the wing.

I had raised the slam panel 6mm, luckily the bonnet line was low, so raising it was no problem if I wanted, I levelled with the wings by adjusting the sprung latch pins each side in the pic below, by pulling down on the spring exposing the 17mm locknut, and adjusting the pin until I was happy with the height. There is usually 4-6 full turns antclockwise before the pins are ejected by the springs, I adjusted 1/8 to 1/4 of a turn then checked the hright.. (It was fun trying to hold the bonnet up with my head, pull down on the spring, and undo the locknut).

TADA. How'd ya like them apples.

Well pleased. Many thanks to Jules for putting me on the track of crash beam and slam panel adjustment to alter the height of the bumper. Now to wash off the grubby marks.

I have tried to make the picture below exagerate the bonnet shutline gap above the grille.

I have the option of pushing the top of the bumper in and I could get away with lowering the bonnet a litle now, but as the pic below shows taken beforehand, I like this bonnet/grille line gap. The pic shows the bonnet was lower than the wings, and the bumper line was quite bad. It was a bright day and it was hard to take a pic without sun glare.

Another pic taken after the facelift's facelift. The lines are vastly improved

I cannot stress the importance of getting the slam panel and crash beam adjusted correctly from its original position, otherwise, right now I could be taking the bumper off to start all over again.

Notes and addendums

On rare occasions the yellow fir tree clip with the little ball on the end (seen on the concave part of the wing in pic 3 by Jules) comes out of the wing attached to the bumper. You just pull it out of its socket on the bumper and push it back into the wing. You then just line up the socket on the bumper( you will notice that this white socket is floating and is able to move up and down allowing vertical bumper movement) and push it onto the little yellow ball on the wing.

I believe it says in a manual somewhere to remove the fir tree clips from the wings, and push them into the bumper, this should only be done if the fir tree clips cannot be located into the socket on the wing, because they may break by needless removal or when refitting the bumper.

If you look close at the crash beam, you remove 4 bolts from each end and remove the crash beam. The single nut at each end holds the slam panel in place while you check its position for possible adjustment. If you look close at the 2nd pic in the how to you will see the slam panel is as high as it will go without stopping the bolts from going back in, luckily this was enough for me as the slam panel must have been resting on the bolts before they were tightened. I first removed a single bolt from each side of the crash beam, and noticed that the crash beam could not be pushed up without making the square holes a little bigger. You have to raise the slam panel because the infil strips tend to rest upon the crash beam so it is best to raise both equally.

Look at pic 5 in the how to, notice the horizontal position of the slam panel has not been altered, the holes each side of the slam panel are far bigger than the bolt, this allows minor adjustment. You will see by the ring made by the top bolt, that when the bolts are inserted and tightened, the slam panel will be in exactly the same place but a few mm higher.

If the forum is browsed you will find a number of threads relating to bonnet jamming and bonnet cable modification. Part is due to the design, part is due to poor bonnet locking pin alignment/lubrication, and the bonnet being on the verge of jamming each time it is released. The modification allows greater force to be applied to the release lever without the cable 2 into 1 assembly coming apart. You can pull your bonnet release and it may be happy to release, it may however be on the verge of poor alignment and may only need a mm or two out of alignment to cause it to jam

Disclaimer:

You are responsible for any work or modifications carried out on your car and you undertake any such work at your own risk. Neither the 75 and ZT Owners Club nor the original authors in this thread can be held liable for anything that may happen as a result of you following this thread's posts.

Any modifications should be reported to your insurance company.

To catch me, you gotta be fast...

To find me, you gotta be smart...

But to be me...!!

DAMN! You must be kidding!

filmpjes op: http://www.youtube.com/rover623Gsi

To find me, you gotta be smart...

But to be me...!!

DAMN! You must be kidding!

filmpjes op: http://www.youtube.com/rover623Gsi

- gerardfennema

- MG-R Regular

- Berichten: 33

- Lid geworden op: zo okt 05, 2014 11:26 am

- Woonplaats: Muntendam

- Locatie: muntendam

Re: voorbumper zakt

Heb mijn bumper weer in orde

Het probleem zat hen in het foam van de bumperhoes deze glijd over de

bots balk heen

Hebben de bots balk op de hoogste stand geplaats en onder de onderste bouten

een extra moer gezet zodat hij naar boven kantelt

Daarna de bumperhoes monteren en het ziet er weer gelikt uit

Het is ongeveer 2uur werk

Het probleem zat hen in het foam van de bumperhoes deze glijd over de

bots balk heen

Hebben de bots balk op de hoogste stand geplaats en onder de onderste bouten

een extra moer gezet zodat hij naar boven kantelt

Daarna de bumperhoes monteren en het ziet er weer gelikt uit

Het is ongeveer 2uur werk